FAQ 10 frequently asked questions about permanent anchors

Where and for what are permanent anchors - When are permanent anchors used?

The so-called scaffolding permanent anchors are required according to DIN 4426 on buildings from a building height of 8 m, or more precisely, DIN 4426 requires permanent anchoring devices for the recurring attachment of scaffolding in the case of panel-type cladding and cladding of facades. (We have an excerpt from DIN 4426 available for download or would be pleased to provide it to you). The tensile and transverse loads mentioned in DIN 4426 do not apply per anchor point, but per running meter of facade length and these can also be dissipated by additional constructive measures in the scaffold itself, by free-standing scaffolds or other special constructions. Permanent anchors are mainly used on ETICS and curtain walls in order to be able to anchor the scaffold securely in future scaffold positions (e.g. new facade coatings and repair work).

How many permanent anchors do I need on my / a construction project?

DIN 4426 does not prescribe a number of anchor points, but states that 2.25 kN per meter of facade length must be absorbed as a force at right angles to the facade and 0.75 kN parallel to the facade. Thus, the number of permanent anchors to be used is determined by the scaffolding grid selected and the corresponding bay lengths of the scaffolding. As with planned scaffolds and brackets, each upright must generally be anchored at the node, it is therefore recommended to provide a permanent anchor at each node. On the one hand, the required load values of DIN 4426 are thus also complied with, on the other hand, this also provides the possibility of being able to provide a bracket scaffold for future scaffolding constructions, as well as the tensioning of tarpaulins and nets. With bay lengths of around 2.50 m, this would mean about 1 permanent anchor per 5 m² facade area. For temporary scaffolding anchors, the rule of thumb is about 1 permanent anchor per 10 sqm facade area. A V-anchor design is also possible and can be included in the calculation. The design resistances for calculating the required number of anchors can be taken from our general building approval Z-21.8-2036.

What is the difference between temporary anchor and permanent anchor

Temporary scaffolding anchors are intended for one-time use only, but can optionally remain in the facade and be plastered over, or possibly removed again. Since our anchor system is made of a high-strength and UV-resistant plastic, our permanent anchors can also be plastered over and remain in the wall. Our concept is in any case based on an anchor construction that remains permanently on the building and is to be seen as a thermal separation element due to the plastic material and almost excludes thermal bridges. Our system as a permanent anchor is not only intended to remain on the building, but is also suitable for the recurring attachment of working and safety scaffolds. When used as a permanent anchor, our system is mounted with a high-strength eye bolt in strength class 8.8 and permanently closed with our cap after unscrewing the eye bolt. In later scaffolding positions, the cap can be unscrewed again and the permanent anchor releases its internal thread for a new scaffolding eye screw for anchoring the scaffold and this for as long as the facade and the building "lives".

Can I use long eyelets below 8 meters eaves height of the building?

In principle, a scaffold with anchors using scaffold eye bolts with a shaft length of more than 7 cm is not considered stable. Theoretically, scaffold positions could also be achieved by stiffening the scaffold with additional diagonals, lattice girders and other constructive measures using long scaffold eye bolts with a shaft length of more than 7 cm. Long scaffold eye bolts must not only counteract tensile and transverse forces, but also compressive loads. Since it is difficult to absorb compressive loads even with structural bracing measures, the use of longer eye bolts than previously described should be generally avoided. Although DIN 4426 only describes building heights of 8 m and more, this refers to "permanent anchoring devices", not to long or short eyelets. The professional associations of the building industry as well as other institutions therefore generally require scaffolding eye bolts with a maximum shaft length of 7 cm, whether with ETICS, curtain walls or simple facades.

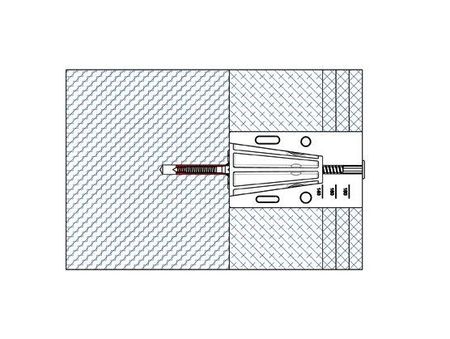

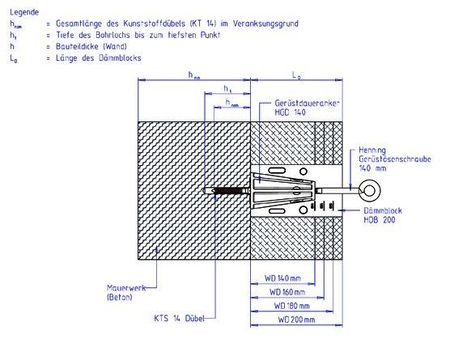

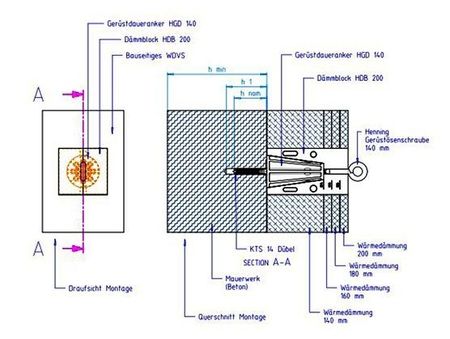

How exactly does the Henning permanent anchor system work?

Our permanent anchor system is characterized above all by its ease of installation, because in addition to thermal decoupling, an extremely favorable price and low weight, our permanent anchor can be installed in 2-3 minutes and thus has clear advantages in terms of economy and application. For the user, not much changes compared to conventional anchoring with ring eyes. First, a 14-hole is drilled, the KT14 plug supplied is inserted and then the permanent anchor is installed by turning it to the left. Now only the eye screw has to be screwed in and the framework can be anchored. As an option, our insulation block can now be attached before or during the facade cladding, which makes it much easier to work on the ETICS panels by accurately fitting the permanent anchor. When dismantling the scaffolding, the eye bolt is then unscrewed and replaced by the sealing cap. This cap is weather and UV-resistant and can be painted with facade paint and varnish to match the facade. According to the anchor protocol created during the initial scaffolding of the building, the anchor point can still be found even after years and the cap is replaced by our eye bolt. This application is possible several times over and significantly exceeds the life expectancy of a facade and its average scaffolding over time.

Who may install permanent anchors?

Again and again there is uncertainty about which profession should and may install permanent anchors. First and foremost, the scaffolding contractor is liable for the stability of his scaffolding and therefore the anchoring of the scaffolding can only be done by the scaffolding contractor. Our permanent anchor system can and may be installed by any contractor who installs our permanent anchors in accordance with the approval. In practice the scaffolder uses short ring eyes for scaffolding, the facade builder should install the permanent anchors in consultation with the scaffolding contractor and then have the scaffold anchored by the erector. This sounds a bit cumbersome at first, but makes a lot of sense on closer inspection. Read on in question 7.

Who is in the warranty for a built-in permanent anchor?

Continued from point question 6. The scaffolding contractor can hardly give a warranty for a part of the facade (in this case the permanent anchor points), because the permanent anchor becomes part of the facade and thus part of the building. This must not only be installed correctly and in accordance with the approval, but also be professionally integrated into the facade. The processing in the ETIC-System or the curtain wall is carried out by the facade builder and he stands for his trade in the overall warranty. Finally, it is also important that the permanent anchors are installed according to an optically attractive grid and therefore, in our opinion, fall under the warranty of the facade. This cooperation should take place in close coordination of the trades and has already proven itself a hundred times in practice. Since the caps should also be painted in the same color as the façade, it is recommended that the façade builder should also install them. He has the right sealants (e.g. acrylic), can apply the original color of the facade after screwing in the caps and at the same time ensure that his work is professionally completed.

How long does it take to install a Henning scaffolding permanent anchor?

The installation of our system is already described under point 5 and takes only 2-3 minutes for the pure permanent anchor installation, as a time reference value which we have determined. With the help of our installation tool, which fits into standard drills, this installation process even takes only 1-2 minutes. Since the insulation block is only attached, we recommend that the installation is only carried out shortly before the ETICS system is attached to the respective anchor point. This procedure can be carried out within seconds and the screwing in of the sealing cap is also extremely fast, as our permanent anchor has a prefabricated internal thread which holds our eye bolts as well as our sealing caps with a perfect fit.

To whom or what does DIN 4426 refer and who is responsible for its implementation?

DIN 4426 is a pure planning standard, not an established construction rule. Therefore, to our knowledge, DIN 4426 is primarily aimed at planners/architects and building owners who are obliged to implement and comply with this standard. Accordingly, every builder-owner who consciously or unconsciously opposes the implementation of DIN 4426 is also liable.

Excerpt from DIN 4426 - This requires the client to provide permanent anchors and describes that permanent anchors are state of the art and prevent damage to the ETICS

Enclosed you will find an excerpt from the leaflet on the anchoring of working and protective scaffolds in facades with thermal insulation composite systems, published by the Federal Guild of Scaffolders and the Federal Association of Scaffolders in March 2009. This is also the source reference.

„Die Verordnung über Sicherheit und Gesundheitsschutz auf Baustellen (Baustellenverordnung-BaustellV) von 1998 fordert vom Bauherren, allgemeine Grundsätze zur Verhütung von Gefahren für Sicherheit und Gesundheit zu berücksichtigen.

Zu diesen Grundsätzen zählt die Norm DIN 4426:2001-09: „Sicherheits- technische Anforderungen an Arbeitsplätze und Verkehrswege“. Sie legt unter Ziffer 7 „Verankerung von Gerüsten an Fassaden“ fest:

„Werden die tragenden Bauteile einer Außenwand mit Platten bekleidet, oder werden Vorhangfassaden angebracht, so sind dauerhaft eingebaute Verankerungsvorrichtungen für Fassadengerüste vorzusehen. Der vertikale Abstand zwischen den Verankerungsebenen darf 4,0 m nicht überschreiten, der horizontale Abstand der Vorrichtungen wird nicht festgelegt.

Die Vorrichtungen sind für folgende Kräfte zu bemessen:

Rechtwinklig zur Fassade 2,25 kN je Meter Fassadenlänge, parallel zur Fassade 0,75 kN je Meter Fassadenlänge.

Beträgt der vertikale Abstand weniger als 4,00 m, dürfen die Kräfte proportional abgemindert werden. An Gebäudekanten (z. B. Traufkanten, Gebäudeecken) sind die angegebenen Kräfte zu verdoppeln.

Auf Verankerungsvorrichtungen darf verzichtet werden, wenn Fassadenbefahranlagen vorhanden sind oder die Außenwandhöhe des Gebäudes 8,00 m nicht überschreitet.“

Wärmedämmverbundsysteme (WDVS) sind plattenartige Bekleidungen der Fassade. Insofern sind die genannten dauerhaften Ankersysteme auch bei WDVS vorzusehen. Der Einbau dieser Daueranker ist keine im Berufsbild des Gerüstbauer-Handwerks enthaltene Leistung und muss von Fachbetrieben des Fassadenbaus realisiert werden.

Daueranker sind Stand der Technik und beugen Schäden vor!

Unabhängig von den Regelungen der Norm DIN 4426 sollten Bauherr und Planer auch bedenken, dass das Bauwerk zu einem späteren Zeitpunkt für Schönheitsreparaturen und/oder Sanierungsarbeiten wieder eingerüstet werden muss. Wenn keine dauerhaften Verankerungssysteme in der Fassade vorhanden sind, so wird jede spätere Einrüstung zu Schäden am WDVS führen müssen.

Ein an langen Ringösenschrauben befestigtes Gerüst muss sich – ungeachtet der Tatsache, dass eine solche Ausführung nicht standsicher ist – unter Einwirkung von Windlasten zwangsläufig bewegen. Die Verformungen der Ankerschraube verursacht Schäden in der Wärmedämmung. Die durch die verformten Anker entstehenden trichterförmigen Schadstellen führen zu Wärmebrücken und haben hässliche optische Beeinträchtigungen zur Folge. Diese Schäden können nur dann vermieden werden, wenn entweder Daueranker eingebaut werden oder die parallel zur Fassade wirkenden Kräfte durch geeignete andere konstruktive Maßnahmen aufgenommen werden können, sodass eine Verformung der Ankermittel in der Wärmedämmung ausgeschlossen wird.

Konstruktionen zur Aufnahme parallel zur Fassade wirkender Lasten.

Wenn ein Bauherr und/oder ein Planer – trotz der guten Gründe, die für Daueranker sprechen – darauf besteht, dass das Gerüst mit „langen Ankerschrauben“ ausgeführt werden soll, so ist dies bei Einhaltung des in den technischen Regelwerken geforderten Sicherheitsniveaus technisch nur dann möglich, wenn entsprechende Konstruktionen zur Aufnahme der parallel zur Fassade wirkenden Lasten ausgeführt werden (z. B. Umleitung der Kräfte parallel zur Fassade über fachwerkartige Rohr-Kupplungskonstruktionen unter den Belagebenen im Eckbereich des Gerüstes in Anker, die lotrecht zur betrachteten Fassade eingebaut sind; Stirnseitige Verankerung des Gerüstes in Erkern, Balkonen o. ä.). Ohne derartige Konstruktionen ist das mit ‚langen Ankern‘ ausgeführte Gerüst nicht standsicher!“

* All questions and statements answered here do not represent a guarantee for their correctness, but are compiled information, from discussions with experts and specialists, appropriate technical literature and empirical values. The author and the operator of this homepage do not assume any liability for this and are excluded. We reserve the right to make changes at any time and correspond to the current state of knowledge of the author. It is the responsibility of each user to inform himself and to comply with the corresponding rules and standards according to the latest state of the art.